Explore more products from this supplier

You may also be interested in

Product Description

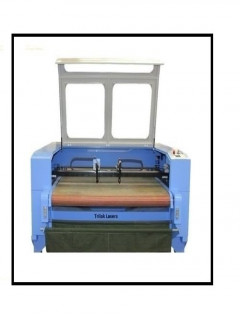

Product Details: Cycle Time With Insertion Of Protective Material 2 or 3 months Automatic Grade Automatic Phase Single Phase Electrical Consumption 10 kw Axis X / Y /Z Axis Positioning Speed + 0.03mm/min Max Cutting Sheet Thickness MS 6mm, SS 3mm, GI 2mm, Condition New Brand Trilok Transmission Precise pinion and rack, dual-drive transmitting Voltage(Volt) 220V 50Hz Material Steel Structure Coolant Tank Capacity 25 Ltr Control Software cypcut Software Machine Type Fiber Laser Cutting Machine Cutting accuracy 0.01 mm Color Blue/Black Frequency 50Hz/60Hz Fiber Laser Head Ray tools Gross Power 10 Kw Laser wavelength 1046 nm Machine table height 300 mm Voltage AC220V+10% 50Hz/60Hz Laser Type Raycus Fiber Laser Load Running Speed 100 meter Features High Speed, Highly Accurate Usage/Application sheet metal cutting X Axis Travel 2500mm Weight 3500kg Y Axis Travel 1300mm Packaging Size 1800 kg Z Axis Travel 220mm Place Of Origin India Warranty 1 Year Autofocus Yes Cutting Capacity 10000 mm/sec max Air Supply Oxygen & Nitrogen Slotting Size 0.1 mm Cooling System Water Chiller Motor Power 750 W Driving System Servo Drive Power Supply 220V Single Phase Spindle Speed no Saw Type no Display Type Computer Packaging Type wooden, plastic rapping Color Printing Color Printing Working Area 2500mm*1300mm Air Supply Psi 1-20 Kgcm Application Sheet Metal Cutting Size 2500mm*1300mm Machine Weight 3500kg Model TIL1325F Capacity 500w Input Voltage 220V Horsepower 13 hp Character Volume Mm 1 mm Cooling Mode Water Cooled Standard Accessories Chiller, Blower, Protecting Glass, Is It Rust Proof Rust Proof Case Weight 3500 kg Cutting Thickness MS 6mm, SS 3mm, GI 2mm Drive System Servo Motor Driven Type Rack & Pinion & Squire Guides Fix Position Precision 0.01 mm Laser Output Control CNC Controlled Laser Power 500W Maximum Motor Speed 10000 mm/sec Operating Temp. 20-35 Compressed Air Requirement Oxygen & Nitrogen Power Consumption Kw 10 Kw Power Source Single Phase Punching Heads Number 1-2 mm Reposition Accuracy 0.01 mm Service City Pune (All India) Temperature Deg Celsius 20-35 Transmission Method Rack & Pinion & Squire Guide Dimensions 3500*2100*1800mm Engine Drive Requirement Servo Drive Engraving Speed No Gas Supply no Work Table Volume Mm 1300mm x 2500mm Working Humidity 5-95 Working Speed up to 10000 mm/sec Product advantage: Stable and reliable light path system and control system. Imported original fiber laser generator with great and stable performance to have lifespan over 100,000 hours. High cutting quality and efficiency with cutting speed up to 25m/min and beautiful,smooth cutting edge. High performance reducer,gear and rack;guide rail and ball screw to guarantee stable running. Application: Widely used in kitchen appliance electrol control box,mechanical equipment,electrical equiment,lighting hardware fittings,elevator manufacturing auto parts, display equipment,haedware and metal processing Samples: The machine is specially used for cutting 0.4-8mm carbon steel;0.4-4mm stainless steel,galvanized steel;0.4-3mm aluminum alloy;0.4-1mm brass and various other thin metal 750W Cutting process parameters: Material Thickness Auxiliary gas Carbon steel ≤8mm Oxygen/air Stainless steel ≤4mm Nitrogen/air Aluminium alloy ≤3mm Nitrogen Brass ≤2mm Nitrogen / oxygen 750W Thickness???MM??? Gas Maximum cutting speed Stainless steel 0.5 Nitrogen ???25m/min 1 Nitrogen 12~18m/min 4 Nitrogen 0.78~1.2m/min Carbon steel 1 Oxygen 12~18m/min 3 Oxygen 3~3.9m/min 5 Oxygen 1.2~1.8m/min 8 Oxygen 0.72~0.84m/min Aluminium alloy 1 Nitrogen 8m/min 2 Nitrogen 2m/min Galvanized sheet 2 Nitrogen 5m/min

Download App

Download App

LASER CUTTING MACHINE

Trilok Laser

Product Name: Fiber Laser Cutting Machine

Product Quantity: 1

Product Price: Rs 2900000

Get a quick quote from this supplier

Please log in to view supplier's Mobile Number